Nitinol, a nickel-titanium alloy, is renowned for its shape memory effect, superelasticity, excellent corrosion resistance, and biocompatibility, making it a critical material in advanced medical devices. Below is a comprehensive breakdown of its applications in medical interventional and implantable devices, classified by medical specialty, with detailed descriptions of each use case.

Notes:

Interventional devices are used for temporary or auxiliary medical procedures, typically during surgery or diagnostics, and are not intended for long-term retention in the body. Nitinol’s superelasticity and flexibility enable precise navigation and operation in complex anatomical environments.

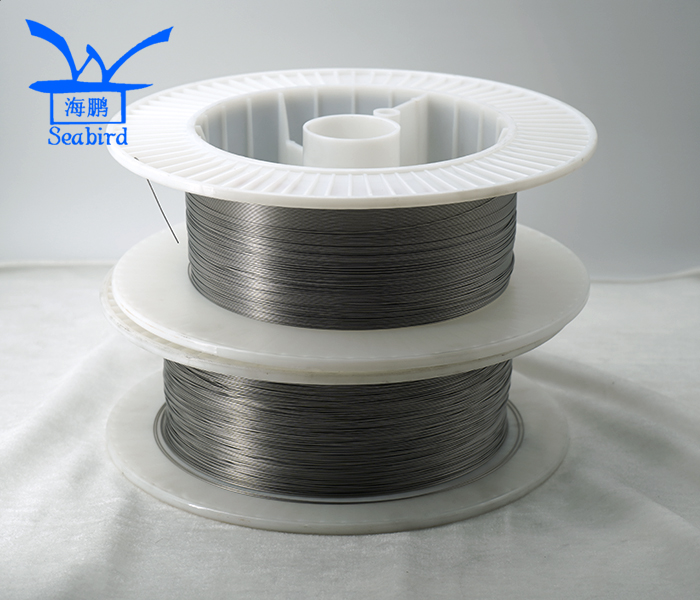

Guidewires: Nitinol guidewires are essential for navigating catheters or other devices into coronary arteries or peripheral vessels during procedures like angioplasty or stent placement. The alloy’s superelasticity allows the guidewire to bend significantly without kinking, ensuring smooth passage through tortuous vascular pathways. Its high fatigue resistance supports repeated flexing during lengthy procedures, while biocompatibility minimizes tissue irritation. Typical Nitinol guidewires have diameters ranging from 0.014 to 0.038 inches, tailored for specific vascular applications.

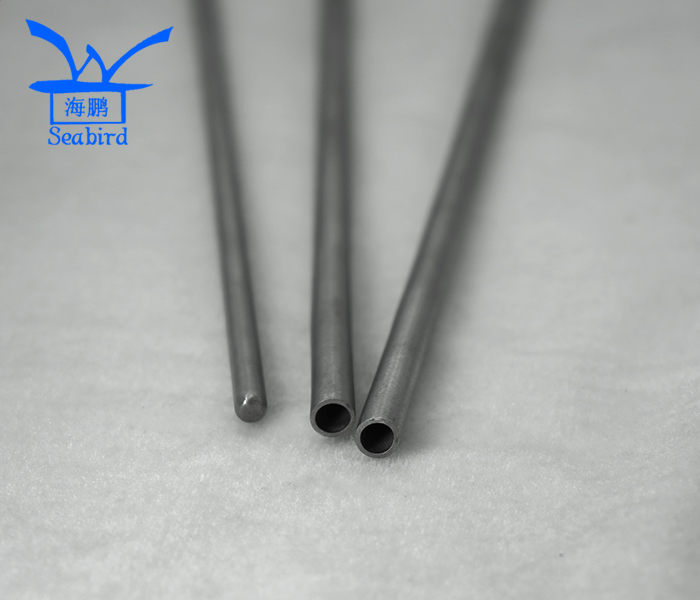

Neurovascular Catheters: Nitinol is used in neurovascular catheters for treating conditions such as cerebral aneurysms, arteriovenous malformations, or ischemic stroke. These catheters leverage Nitinol’s superelasticity to navigate the intricate and delicate cerebral vasculature, enabling precise delivery of embolic coils, stents, or thrombectomy devices. The alloy’s ability to recover its shape after extreme deformation ensures reliable performance in tight, curved vessels. Nitinol’s radiopacity (often enhanced with coatings) aids visibility under fluoroscopy, critical for neurosurgical precision.

Endoscopic Components: Nitinol is incorporated into endoscopic tools such as graspers, cutting instruments, and retrieval baskets used in minimally invasive surgeries (e.g., cholecystectomy or urological procedures). The superelasticity of Nitinol allows these components to flex and maneuver within confined spaces, such as the bile duct or urinary tract, without permanent deformation. For example, Nitinol retrieval baskets can expand to capture kidney stones and collapse for safe withdrawal. Its corrosion resistance ensures durability in bodily fluids, and its biocompatibility reduces the risk of adverse reactions.

Implantable devices are designed for long-term or permanent implantation to treat or support bodily functions. Nitinol’s shape memory effect, superelasticity, and biocompatibility make it ideal for devices requiring durability, precise functionality, and compatibility with human tissue.

Stents: Nitinol stents, such as coronary or peripheral vascular stents, are deployed to support vessel walls and prevent narrowing (stenosis) in conditions like atherosclerosis. The alloy’s shape memory effect allows stents to be compressed into a delivery catheter and expand to their predetermined shape upon reaching body temperature, ensuring a secure fit against the vessel wall. Superelasticity accommodates vessel movement, reducing the risk of fracture. Nitinol stents often feature tensile strengths exceeding 1000 MPa and elongation rates above 20%, providing robust support. Drug-eluting Nitinol stents further reduce restenosis by releasing therapeutic agents.

Cardiac Occluders: Nitinol cardiac occluders, such as those for atrial septal defects (ASD) or patent foramen ovale (PFO), use the shape memory effect to close congenital heart defects. These devices are delivered in a collapsed state via a catheter and expand into a double-disc configuration to seal the defect upon deployment. Nitinol’s flexibility ensures conformability to irregular defect shapes, while its biocompatibility minimizes thrombus formation. The precise shape recovery and fatigue resistance ensure long-term stability in the dynamic cardiac environment.

Filters: Inferior vena cava (IVC) filters made from Nitinol prevent pulmonary embolism by capturing blood clots before they reach the lungs. The alloy’s superelasticity allows the filter to collapse into a delivery catheter and expand into a conical or umbrella shape upon release. Nitinol’s corrosion resistance ensures durability in the bloodstream, and its shape memory enables retrievable filters to be removed after the risk of embolism subsides. These filters are designed to withstand cyclic loading from blood flow, maintaining structural integrity over years.

Drug-Releasing Devices: Nitinol drug-eluting stents combine the alloy’s mechanical properties with polymer coatings that release antiproliferative drugs to prevent restenosis. The shape memory effect ensures accurate stent deployment, while superelasticity maintains vessel patency under dynamic conditions. Nitinol’s high strength supports thin strut designs, reducing vessel trauma while maximizing drug delivery surface area. These devices are critical in treating complex lesions in coronary or peripheral arteries.

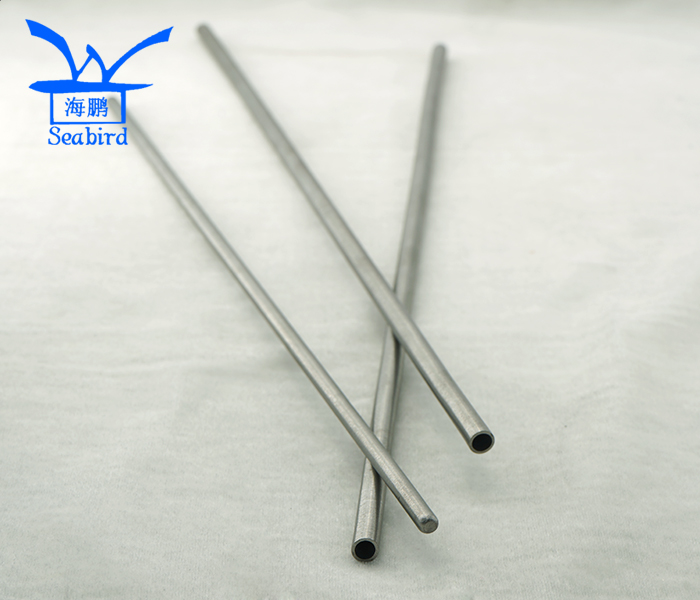

Bone Fixation Devices: Nitinol bone fixation devices, such as bone screws, plates, or staples, aid fracture healing by applying controlled compression. The shape memory effect allows staples to contract upon reaching body temperature, pulling bone fragments together to promote fusion. Superelasticity ensures flexibility under mechanical stress, reducing the risk of device failure. Nitinol’s biocompatibility and corrosion resistance make it suitable for long-term implantation, with tensile strengths above 1000 MPa supporting robust fixation in load-bearing bones like the femur or tibia.

Spinal Correction Devices: Nitinol spinal correction rods are used to treat deformities like scoliosis or kyphosis. The shape memory effect enables rods to gradually correct spinal curvature as they revert to their pre-set shape at body temperature, applying gentle, continuous force. Superelasticity accommodates spinal motion, reducing stress on adjacent vertebrae. Nitinol’s fatigue resistance ensures durability under cyclic loading, and its biocompatibility minimizes inflammation, making it ideal for pediatric and adult spinal surgeries.

Orthodontic Devices: Nitinol archwires are a cornerstone of orthodontic treatment, providing continuous, gentle force to align teeth. The superelasticity of Nitinol allows the wire to deform under biting forces and return to its original shape, delivering consistent corrective pressure over weeks or months. Compared to stainless steel, Nitinol archwires require fewer adjustments, improving patient comfort. The alloy’s corrosion resistance withstands saliva exposure, and its biocompatibility ensures safety in oral environments. Nitinol wires typically have diameters of 0.016 to 0.025 inches, optimized for various treatment stages.

Sutures/Anchors: Nitinol sutures and anchors are used to repair soft tissues, such as ligaments or tendons, in procedures like rotator cuff repair or anterior cruciate ligament (ACL) reconstruction. The shape memory effect enables anchors to expand or lock into bone upon deployment, securing sutures without knots. Superelasticity ensures flexibility under tissue movement, reducing the risk of anchor pullout. Nitinol’s corrosion resistance and biocompatibility support healing without adverse reactions, with high tensile strength ensuring reliable fixation in dynamic joints like the shoulder or knee.

Artificial Joints/Prosthetic Components: Nitinol is used in components of artificial joints (e.g., hip or knee prostheses) or other prosthetic implants, leveraging its corrosion resistance and high strength for durability. Superelasticity allows components to absorb mechanical stress, mimicking natural joint flexibility. The alloy’s biocompatibility ensures compatibility with surrounding tissues, reducing wear and inflammation. Nitinol’s high fatigue resistance supports millions of load cycles, critical for long-term joint function.

Micro-Sensors/Actuators: Nitinol micro-sensors and actuators are implanted for in-body monitoring or actuation, such as in glucose sensors or drug delivery systems. The shape memory effect enables actuators to open or close micro-valves in response to temperature or electrical stimuli, while superelasticity supports flexible sensor designs. Nitinol’s corrosion resistance ensures reliability in bodily fluids, and its biocompatibility minimizes immune responses. These devices often use ultra-thin Nitinol foils or wires (e.g., 0.05 mm thick) for miniaturization.